|

|

|

|

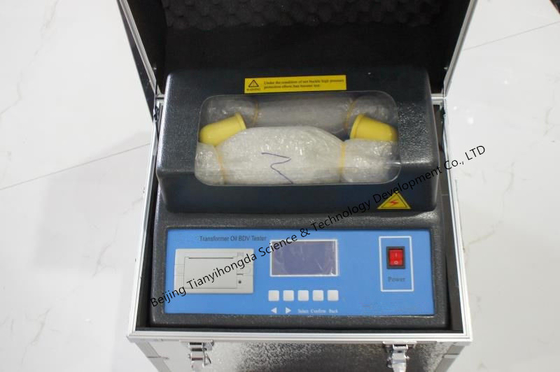

Transformer Oil Dielectric Strength Tester Electrical Testing Instruments , Temperature Display Electrical Testing Tools

Product Details:

Payment & Shipping Terms:

|

| Type: | Mostly Oil-filled Insulation Type | Feature: | Simple Operation |

|---|---|---|---|

| Function: | Display By Large-screen LCD And Prompt By Chinese Menu. | Voltage Distortion Rate: | <3% |

| Highlight: | electrical testing tools,electrical circuit tester |

||

Transformer Oil Dielectric Strength Tester With the function of displaying the measured temperature and system clock

Many power systems, railway systems, large-scale petrochemical plants and enterprises have a lot of electrical equipment whose internal insulation are mostly oil-filled insulation type, and therefore, test on insulating oil dielectric strength is common and necessary. To meet the needs of the market, we have developed and produced a series of insulating oil dielectric strength testers. This instrument, by using a single-chip microcomputer as the core, can operate in full automation with high accuracy, greatly improving work efficiency and reducing the labor intensity of workers. Moreover, it is small in size and convenient to carry.

KEY FUNCTION AND FEATURE:

1. With a microprocessor, automatically fulfill the withstand voltage test for oil circulation with a range of 0~80KV (including boosting, maintaining, mixing, standing, calculation, printing and other operations)

2. Display by large-screen LCD and prompt by Chinese menu.

3. Simple operation. The machine will automatically complete the withstand voltage test on one cup of sample oil after simple setting by the operator. Breakdown voltage value of 1 to 9 times and recurrent

times will be automatically saved. After the test, the thermal printer will print each breakdown voltage value and average value.

4. Power-down preservation. It can save 100 tested results and displaying current ambient temperature and humidity.

5. Adopt a single-chip microcomputer to boost the voltage at an even speed. The voltage is accurate at 50HZ, ensuring the whole process easy for control.

6. Equipped with over-voltage, over-current and limit protections to ensure the safety of operators.

7. With the function of displaying the measured temperature and system clock.

8. Communicate with computer with a standard RS232 interface.

![]()

① Thermal printer --printing the test results

② LCD --displaying the menu, cues and test results

③ Operating keys:

For increasing the setting value after pressing “SELECT”

For decreasing the setting value after pressing “SELECT”

SELECT—for choosing functions (the item selected is on reverse display)

CONFIRM—for executing the function

BACK –for exiting the operating interface

④ Power switch and indicator

MAINTENANCE:

1. This equipment shall not be exposed in moist environment.

2. Keep the oil cup and the electrodes clean. Fill the cup with fresh transformer oil for protection during its idle. Check the electrode distance and check the tightness between the electrode tip and electrode bar screw thread before the cup is used again.

There is type test report for it, test items as following:

|

Type Test Items

|

1. appearance and structure 2.function 3. electrical device performance 4.low temperature performance 5.high temperature performance 6.alternating temperature humidity7.vibrationendurance 8.incline drop test 9. electrical device life 10. static electricity and elecro-discharge immunity test 11.radio frequency electromagnetic field radiated immunity test 12.surge impact immunity test 13. power frequency magnetic field immunity test. 14. Adjacent interference test 15.short-circuit withstand impact test 16. fire hazard test 17. power consumption test 18. protection grade test 19. gripping strength test of grip structure. |

Fax: 86-10-63330700